Key Features

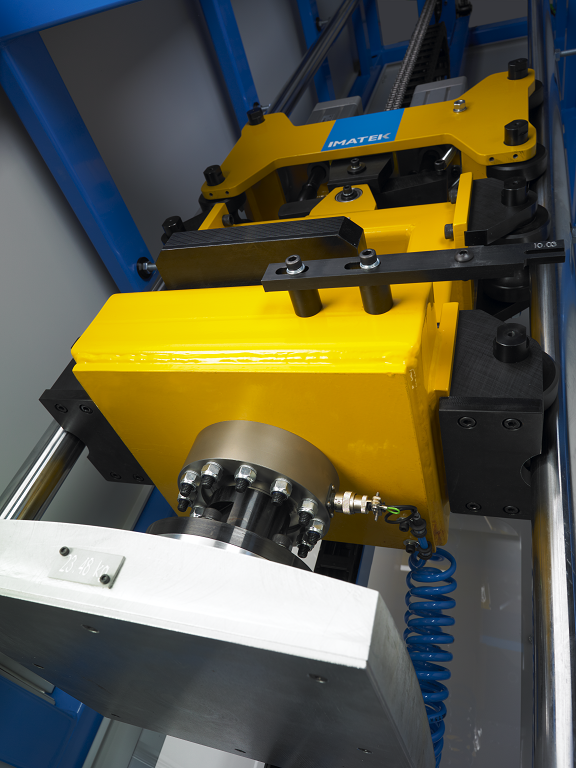

The IM100 is a medium- to high-energy drop weight tester primarily used for compression testing of energy absorbing materials and structures in the automotive industry. Systems are designed and built to a customer’s individual requirements, which means specifications such as the drop height, the impact mass and the size of the specimen area can be precisely tailored.

- Laboratory grade instrumentation and very rigid construction provides accurate and repeatable results.

- Large specimen area with T-slotted base allows great flexibility for testing end-products.

- A guided mass system ensures that the impact geometry is correct throughout the test, and errors due to friction are minimised. Reinforced guide bar mountings in the impact zone allow high off-axis loads to be accommodated.

- Accurate and repeatable drop parameters ensures consistency between tests.

- Easily interchangeable contact parts simplify maintenance and reduce the cost of ownership.

- High levels of safety prevent possible harm to the operator.

- High-quality, easy to use control and analysis software ensures consistency and enhances throughput.

- Impact mass range from 10kg to 500kg. Variable mass increments of 10kg

- Drop height range 100mm to 4000mm.

- Maximum allowable force 500kN.

- Temperature range (optional): -70°C to +200°C.

Options

- Temperature conditioning chamber: provides the ability to test specimens at controlled temperatures between -70°C and +200°C.

- High repeat rate option: for fatigue testing at up to 8 impacts per minute.

- Dynamic displacement system: provides a continuous high-speed measurement of deformation of the specimen throughout the impact. Useful in situations where large deformations are present, for example energy absorption tests.

- High speed video: with fully-integrated camera control and acquisition of the video sequence, and analysis including image tracking and video metrology.