Key Features

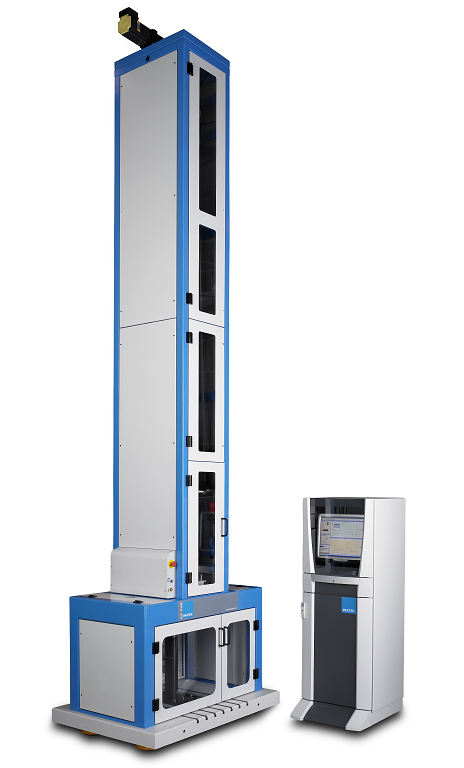

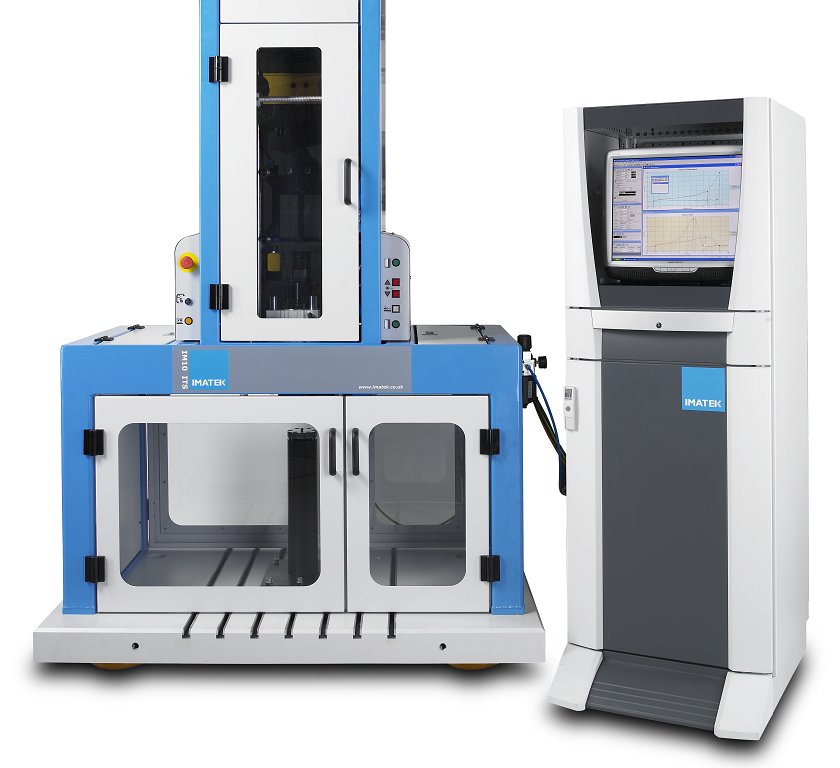

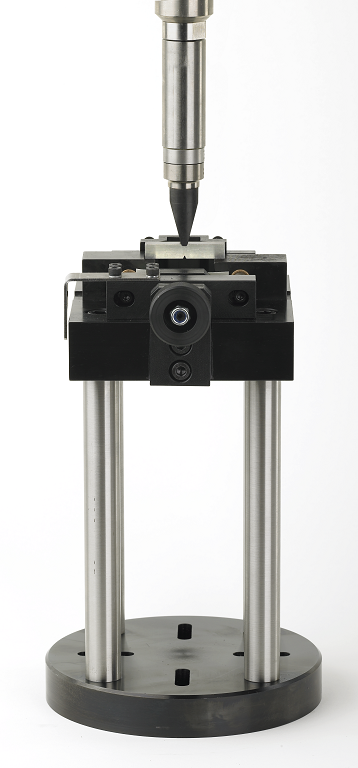

Models in the IM10 range are highly versatile testers for performing a wide range of medium energy impact tests on both standard-form specimens and end products. They feature interchangeable mass carriages, flexible fixture options and optional acceleration for high-speed testing. Their benefits are appreciated by customers in the aerospace, automotive and academic sectors amongst others, and they are used to test metals, polymers and composite materials.

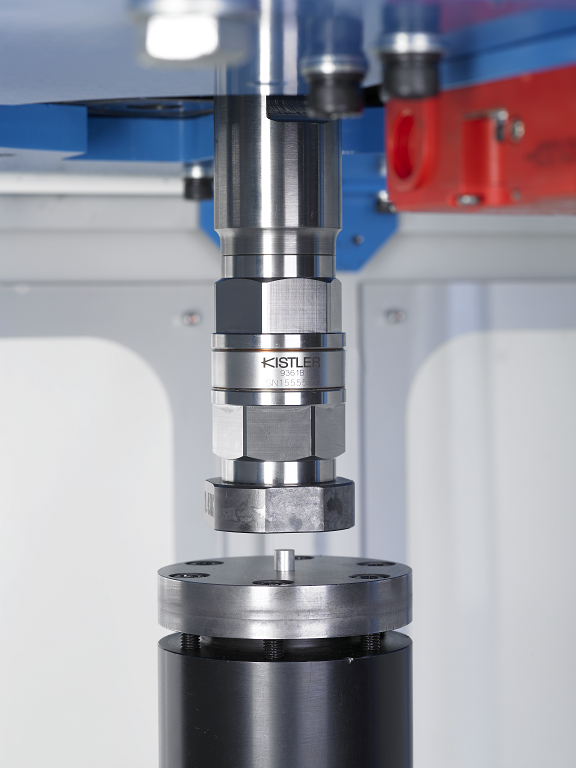

- Laboratory grade instrumentation and very rigid construction produces accurate and repeatable results.

- Large specimen area with T-slotted base allows great flexibility for testing assemblies and finished products.

- A guided mass system ensures that the impact geometry is correct throughout the test, and errors due to friction are minimised.

- Accurate and repeatable drop parameters ensures consistency between tests.

- Easily interchangeable contact parts simplify maintenance and reduce the cost of ownership.

- High levels of safety prevent possible harm to the operator.

- High-quality, easy to use control and analysis software ensures consistency and enhances throughput.

- Impact mass range: 2kg to 100kg.

- Drop height range: 50mm to 3000mm.

- Impact velocity range: 1m/s to 7.7m/s, or to 20m/s with acceleration option.

- Temperature range (optional): -70°C to +200°C.

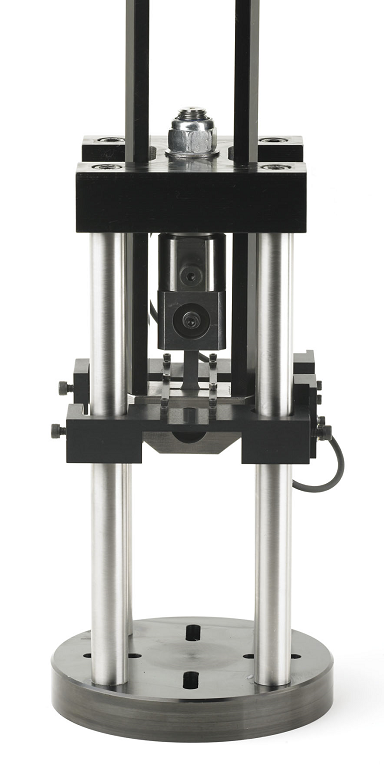

Standard Fixtures

- Plaque anvil: ASTM D3763, ASTM D5628, EN ISO 6603.

- Film anvil: ASTM D1709, ISO 7765.

- Composite coupon anvil: ASTM D7136, AITM1-0010, JIS K 7089.

- High-rate tensile fixture: for flat and dumbbell specimens, able to apply strain rates in excess of 1000/s.

- Cylinder crush anvil: for investigating flow stress behaviour of metallic materials.

- Charpy and Izod fixture: ASTM E23, EN 10045, ISO 148, ISO 179, ISO 180, ISO 14556, ISO 13802.

- Flat anvil used to measure cushioning performance of energy absorbers

Options

- High velocity: a catapult system provides an additional 1000J of impact energy and impact velocities of up to 20m/s (dependant on impact mass).

- Specimen strippers: used to separate the specimen and the striker when binding occurs during the test.

- Second impact prevention system: to prevent the mass carriage hitting the specimen a second time in the case of rebound tests.

- Temperature conditioning chamber: provides the ability to test specimens at controlled temperatures between -70°C and +200°C.

- Dynamic displacement system: provides a continuous high-speed measurement of deformation of the specimen throughout the impact. Useful in situations where large deformations are present, for example energy absorption tests.

- High speed video: with fully-integrated camera control and acquisition of the video sequence, and analysis including image tracking and video metrology.

Please note: the IM10 range is not available in all geographical areas due to licencing restrictions.