Models in the IM1 range of impact testers are designed for low energy applications, between 1J and 120J. They are primarily intended to test according to standard methods, but they are also sometimes used for non-standard testing and research. All models are fitted with laboratory grade precision load cells, and all come complete with Impacqt software for data acquisition and analysis.

The IM1F is a tester for polymeric films, according to test standards ASTM D1709 and ISO 7765. It is exceptionally easy to use with high throughput and outstanding reliability, for use in production environments.

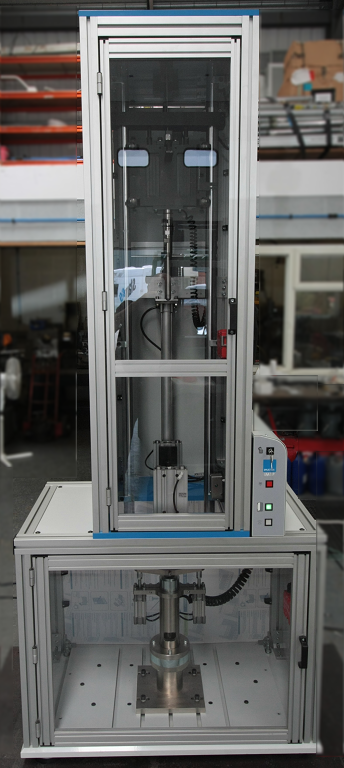

The IM1C is a tester for composite coupons, according to the following standards: ASTM D7136 (compression after impact), AITM1-0010 and JIS K 7089. We can supply custom fixtures as required for non-standard tests. The IM1C is fitted as standard with a secondary impact prevention device to automatically catch the impact mass after it has rebounded off the specimen.

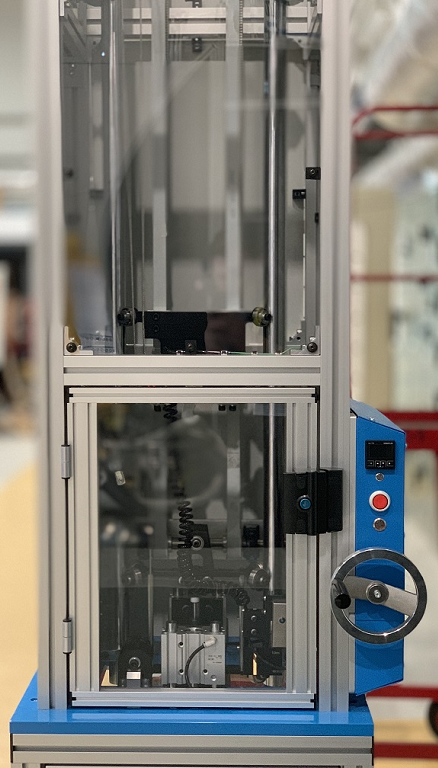

The IM1P is a tester for polymer plaques, according to the following standards: ASTM D3763, ASTM D5628 and ISO 6603. We can supply custom fixtures and strikers for non-standard testing. When testing tough, ductile specimens there is the possibility of the specimens being tightly bound to the striker at the end of the test and to cope with this the IM1P can be fitted with a powerful specimen stripper device that forces the two apart.

The IM1P can optionally be supplied with a temperature conditioning chamber that allows testing at a temperature range from -70°C to +200°C.