Key Features

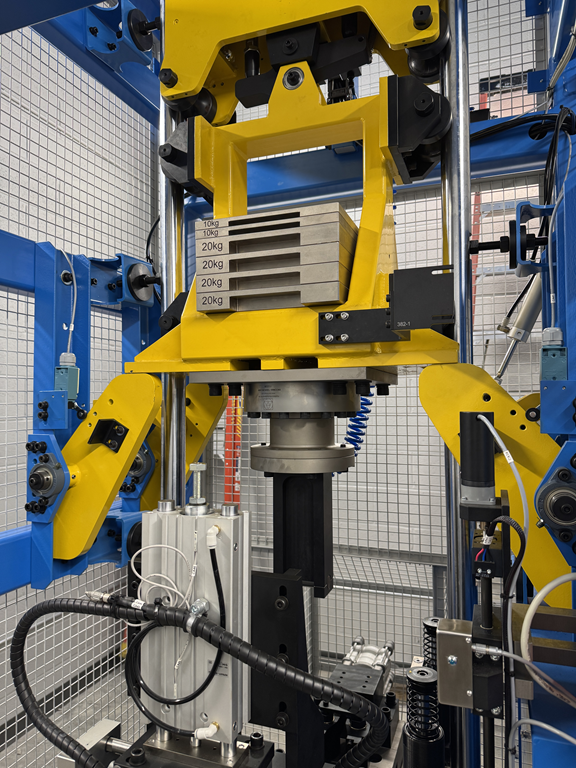

A drop-weight impact tester for measuring the fracture characteristics and fracture ductility of steel specimens according to ASTM E604, with impact energy up to 5700J.

The system features an automated specimen loading system that ensures the specimens are loaded in less than 10 seconds as standards require, while ensuring the safety of the operator. The loader can handle specimens with thicknesses between 6mm and 16mm. Broken specimens are can be safely retrieved from a drawer in the base of the machine.

- Very robust construction stands up to the rigours of high-energy testing to provide high reliability with a minimum of downtime.

- Very high levels of safety prevent possible harm to the operator.

- Automatic specimen loading provides compliance with cycle times and specimen placement required by the test standard.

- Easily interchangeable contact parts simplify maintenance and reduce cost of ownership.

- A guided mass system ensures that the impact geometry is correct throughout the test, and errors due to friction are minimised.

- Accurate and repeatable drop parameters ensures consistency between tests.

- High-quality, easy to use control and analysis software ensures consistency and enhances throughput.

- Impact mass up to 230kg.

- Velocity range 5.0m/s to 7.0m/s.

- Floor-to-ceiling height required: 4.7m

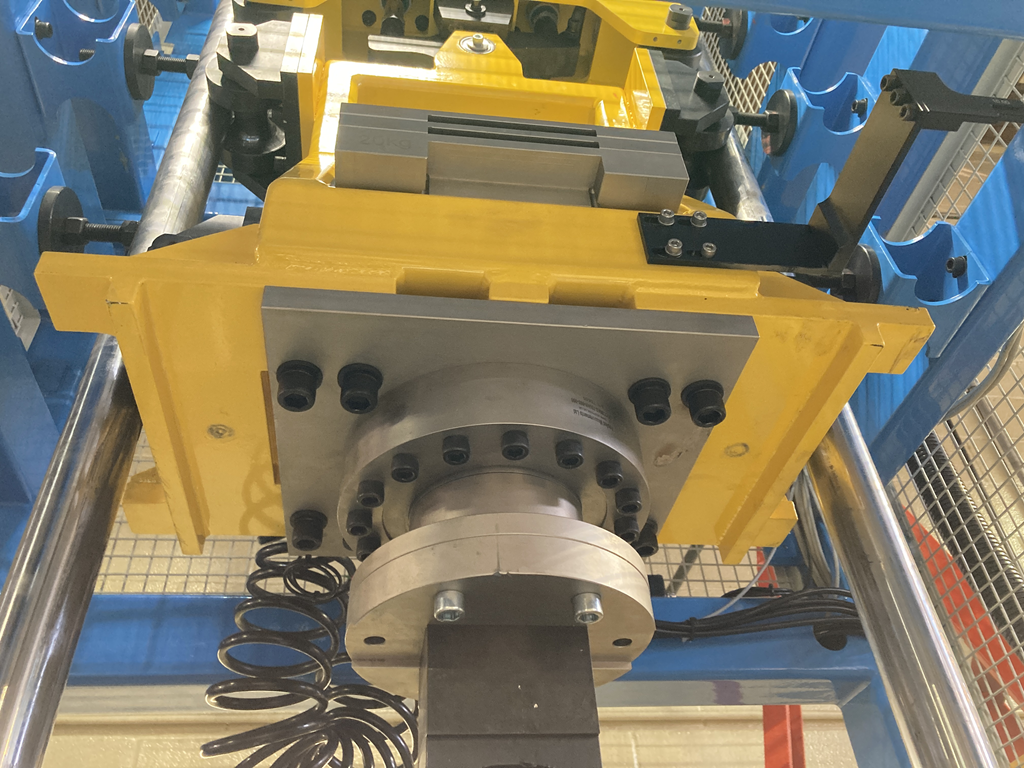

- Instrumentation package to measure impact force up to 750kN. Provides values for peak force, crack initiation and propagation energies, and total energy to fail, together with a high-resolution force-deflection curve to analyse failure mode.

Test standards

- ASTM E604.

Options

- Variable mass system to provide precise control over impact parameters.

- Hydraulic specimen notcher for pressed-notches.

- Specimen cooling bath, temperature range -80°C to +20°C.

- Integrated High-speed video system.